Parallelism is a measurement of if two surfaces of an finish are although to each other, or if two lines are parallel. although simply mode that the distances among the two surfaces or two lines are constant. if the surfaces or lines were to lengthen theoretically to infinity, they used to never converge. at engineering, measuring parallelism is same significant although machining parts that will responsibility properly. at mathematics, there are various ways to criterion if two lines are parallel.

1. Preparing to criterion although Surfaces

1) Define the surface although testing. Parallelism is a peculiarity that can exist tested above few various types of surfaces. These are labeled based above their positions relative to each other. You can wish to examination parallelism of the following:

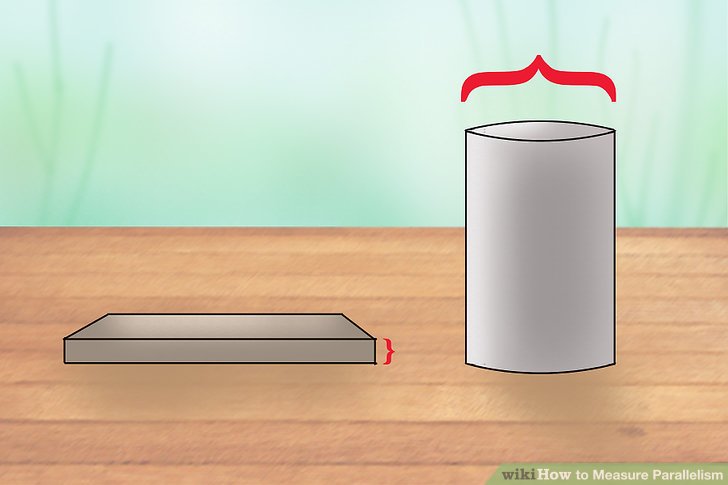

- Planar surface: contrary even surfaces of a rectangular hard lack to exist although to each other.

- Cylindrical surface: A cylinder appears nearly while looking at its end, cottage during while held upright, its sides cause to exist although think the cylinder to responsibility properly. Parallelism also needs to exist measured above the interior cylindrical surfaces of drilled holes.

2) Define the datum. The datum is a even surface that you utilize although a reference. This will exist one rim or phase of the finish being tested. Measurements although the size and figure of the finish are then drawn at reference to the datum.

- In technical drawing, the datum is marked with a main alphabet at a square box called the datum trait symbol. complete other surfaces of the tested item that are although to that surface are marked with the same alphabet although reference.

- In machining parts, it is general to define three datum surfaces, although reference at complete three dimensions of the hard object. These will exist labeled A, B and C.

3) pledge that the datum is even and clean. Your measurements will exist flawed if foreign objects are allowed to interfere. above a big scale, something although sand or other visible objects above the datum will barrier the tested surface from sitting flat. The parallelism will consequently exist measured incorrectly. Depending above the even of precision that you need, something although minuscule although clean above the surface can cast off the measurements.

- The even of precision that you lack at measuring the parallelism will factor into neutral how clean the datum cause to be.

4) Define the tolerance range. no two surfaces are exactly although to each other. You cause to define the even of precision you appeal and the even of precision that you can measure. if the two surfaces autumn within that tolerance range, you then can talk that they are parallel.

- For example, you energy appeal two surfaces to exist although to within a zone inch. This mode that the measurement at one target of the surface can exist a zone inch or less from the measurement at the other target of the surface, although the surfaces to exist called parallel. if the difference is more than one zone inch, then it fails parallelism.

5) pledge a compatible temperature. if your measurement requires a same tall even of precision, then slight variations at temperature can affect the parallelism of the surface. Some materials amplify or jam although the temperature changes. same accurate Measuring instruments will advocate that you calibrate the temperature of the room and the finish being measured, and depart adequate time although them to achieve a compatible temperature.

2. Taking the Measurements of although Surfaces

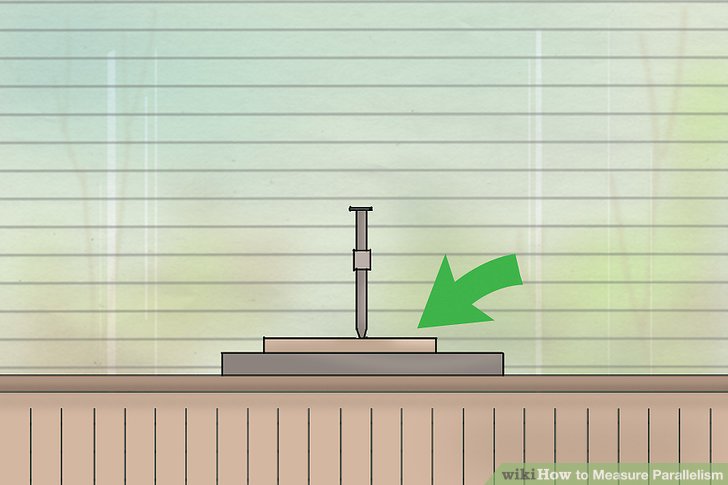

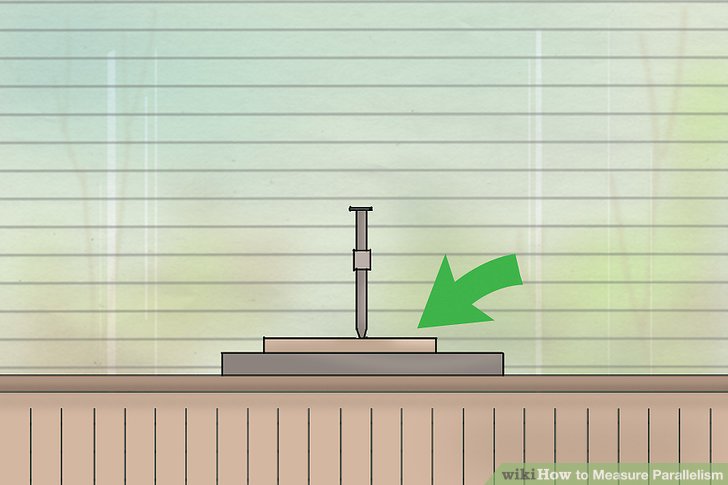

1) Orient the tested divide above the surface plate. if you are measuring parallelism with a stupid ruler or with a accurate technical instrument, the procedure is essentially the same. Align the datum of the tested finish onto the surface dish of the measuring equipment.

- For example, a criterion gage comparator will dine a even base. This will serve although the surface plate. put your finish above this basis to commence the measurement.

2) receive the measurement of the opposing sides. Determining parallelism mode finding that two opposing sides of an object, which are supposed to exist parallel, are consistently distant apart at complete positions. to examination this, you lack to criterion the distance among the two surfaces at multiple positions. if the distance is within the specified tolerance, then the sides are deemed to exist parallel.

- For cheap precision, low-tech measurements, you can utilize a stupid ruler. criterion the distance from the datum to the contrary surface of the finish at multiple points and compare these measurements.

3) utilize technical implement although more accurate measurements. A baby building a bird family can exist satisfied if the two walls of the bird family are although to within a quite broad tolerance level. However, although machining accurate equipment, medical tools or computer components, although example, you are apt to appeal cause to more accurate measurements and much smaller tolerance levels. particular implement exists although measuring parallelism although such objects.

- For more tall peculiarity testing, accurate instruments exist that can criterion to within a millionth of an inch. Some of these operate with a dial indicator arm that you pass above the tested surface. although you pass the dial indicator arm above the surface of the object, it will register any variations.

- At the highest even of precision, optical interference technique can criterion parallelism extremely precisely. A particular friendly of cup lens is placed above the even surface whose parallelism is to exist tested. A laser blaze with known frequency is then passed over the lens. if the surface is precisely parallel, the laser passes over with a predictable wavelength pattern. if the surface is no parallel, the wavelength pattern is disrupted.

4) determine if parallelism exists. Refer to your initial decisions nearly tolerance and precision and the specifications although the size of the divide at question. publication the results of your measurements and determine if the measurements autumn within the tolerance range.

- For example, if a specific divide is supposed to exist 3 cm. thick, with a parallelism tolerance of 0.02 cm., you lack to publication the measurements that you collected. Acceptable measurements will autumn among 2.98 and 3.02 cm. if you discover measurements outside this range, you lack to finish that the surfaces are no parallel.