Horizontal Vertical Flaming Tester

Horizontal vertical flaming tester is designed according to the relevant standard of UL94-2003 and UL746C-2000 Conform to UL94, ISO 9773,IEC 60695-11-3,IEC60695-11-4,IEC60695-11-10.Test flames-50W and 500W. Apply to detect the flammability of the V-0, V-1 and V-2, 5V and ,VTM-0、 VTM-1、 VTM-2grade materials.

Features

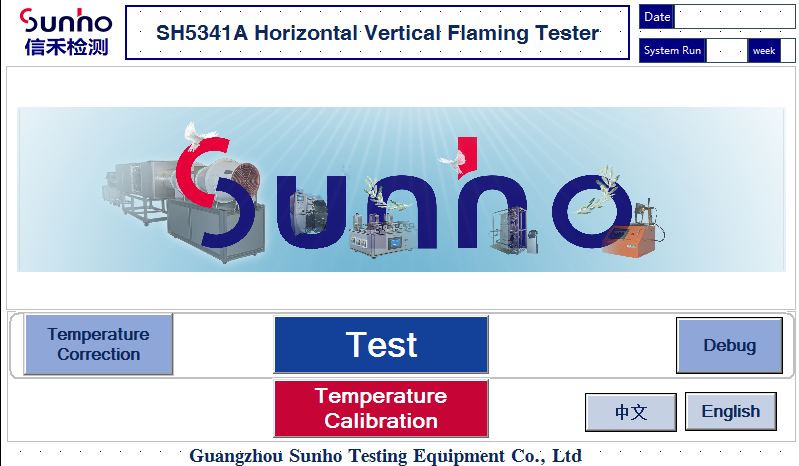

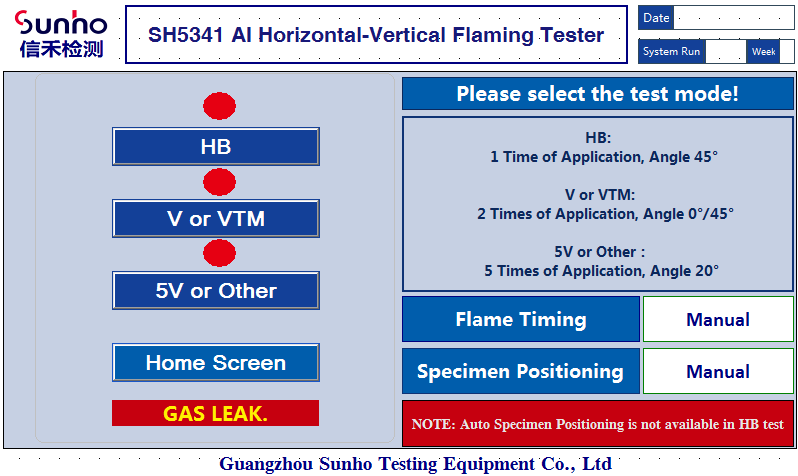

Visualized Interface: user-friendly 7 inches touchscreen;

Programmable PLC Control: parameters easily preset

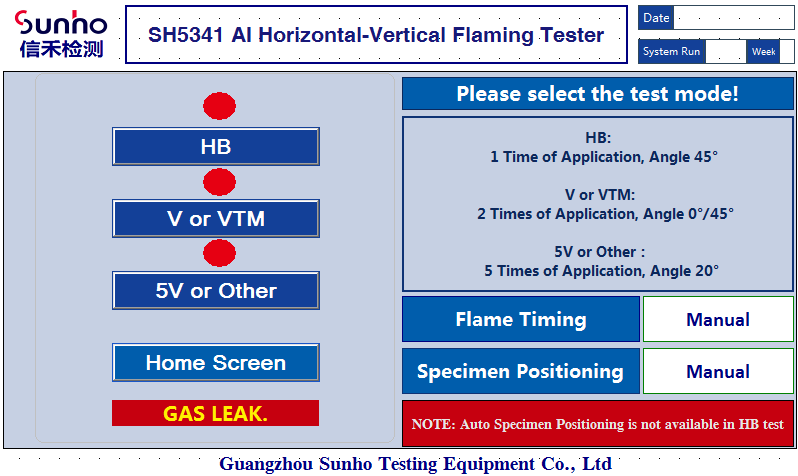

3 Initial Modes: built in with 3 modes for materials with different standard classifications(HB/ V&VTM / 5V), allowing an easy control over the whole test process.

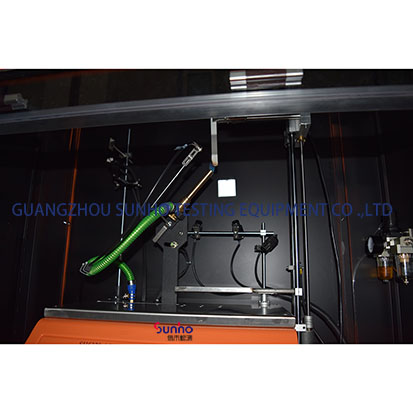

UL Bunsun Burner: effectively premix the gas with air, and generate the 50W/500W flame compliant with standard.

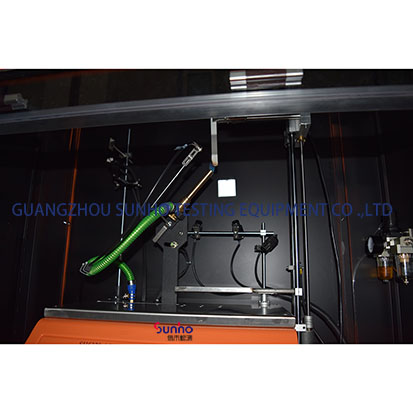

Burner Angle Preset: the UL-standard Bunsun burner is adjustable to 0°/20°/45° accurately by the electric motor

Accurate Gas Control: high-precision flowmeter and gas pressure gauge/regulator

AI Flame Detection: the SUNHO EYE SYSTEM would capture the flaming moment intelligently, and record the time automatically;

AI Sample Positioning (not applicable for HB mode): Before test, the SUNHO NAVIGATOR would record the exact specimen position. During test, the Bunsun burner would be automatically driven to the coordinate following the recorded specimen position (with a distance given by standard)

Stable and Exchangeable Sample Holders: equipped with multiple sample holders for the tight fixing of specimens of different types

Flame Confirmation System: displaying the temperature rising time and flame temperature on screen. (included 50W/500W copper block and K-type thermocouple for calibration purpose)

Draught-Free Environment: fume hood(≥0.5m³) with inner wall illuminance≤20lx. With switch to turn on/off the extraction fan & lighting system;

Secure Protection: short circuit protection, overheat protection;

Artificial intelligent new function

1、Using laser detection to sensor and automatically keep the space between specimen and flame;

2、Fume hood have flammable gas warner, to monitor the density of the gas

Technical Parameters:

1.Use gas or liquefied petroleum gas as the source gas of the pilot flame (Under the conditions of the proposed, suggest the elect of temperament better gas )

2.Diameter of the burner(IEC60695-11-3 Figure A1: 9.5 ± 0.3mm, length 100mm±10, has the air-conditioned hole.

3. Height adjusted from 20mm to 175mm. (provide flame height gauge)

4.Imposing time and holding time of the flame can be adjustable:0 to 99 minutes and 99 seconds. The test process can automatic control.

5.Touch screen display the test data

6.Fume hood capacity:0.75m³

7.Including the infrared remote control

8.Test sample (blowtorch) can follow in vertical (or horizontal) direction.

PLC+Touch screen

Have U type manometer, glass rotameter, and temperature measure device(copper block and thermocouple)

Test Mode:

1. 50W horizontal test(fire hazard test for HB level material)

Flame height: 20±0.1㎜

Burner's angle: 45°

Burning test: 1 time

Test process: After pressing the start button, the burner would automatically lean to a 45° angle and apply heat on the specimen through flame. When the time of flame application(TA) is due, the burner would automatically withdraw from the specimen and the afterflame time t1 wound be simultaneously counted.

2. 50W vertical test(flame test for V-0/V-1/V-2 level material)

Flame height: 20±0.1㎜

Burner's angle: 0°

Burning test: 2 times

Test process: After pressing the start button, the burner would automatically lean to a 0° angle and apply heat on the specimen through flame. When the time of flame application(TA) is due, the burner would automatically withdraw from the sample and the afterflame time t1 would be simultaneously counted. When the t1 ceases, the burner would be replaced, starting the second test in the same procedure.

3. 500W test(flame test for 5V level material)

Flame height: 40±2㎜

Burner's angle: In case the molten drips drop into the burner, the burner is recommended to keep a 20° angle with the Z axis.

Flaming : 5 times

(The inner flame should contact exactly with the center of the sample's lower surface.